- Gold Supplier from Alibaba

- Global 简体中文

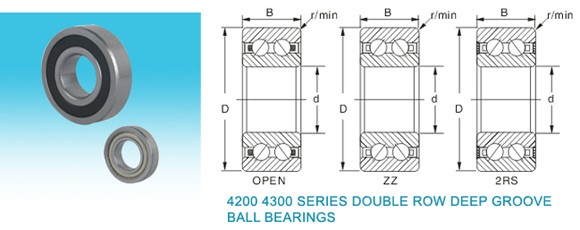

Double Row Deep Groove Ball Bearing (4200,4300, 4200A, 4300A Series)

Double Row Deep Groove Ball Bearings have the same design as Single Row Deep Groove Ball Bearings.

1. Double row deep groove ball bearings with single row deep groove ball bearing on the design. This kind of bearing has uninterrupted deep groove, between the ball and bearing raceway height to cooperate. In addition to the radial load, they also can withstand the two-way axial load.

2. Double row deep groove ball bearing is very suitable for single row bearing to bearing load bearing configuration. In outer diameter and inner diameter of the same case, double row bearing is slightly wider than single bearing, but the load capacity is significantly higher than in 62 and 63 series single row bearing.

1. The bearings have low friction and very little noise or vibration,

2. These characteristics make

3. them to be available for situations of high speed, high precision,

4. low friction and low noise operations.

bearings are engineered for use in high-speed, high precision applications for: Agriculture, Automotive, Chemical, General industrial, Utilities.

| Bore | Chamfer r/min | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing No . | d | O.D. | Width | mm | Load Rating | Ball Complement | Maxrunout speed | Weight | |||

| mm | D | B | |||||||||

| mm | mm | Dynamic | Static | No. | Size | Grease | Oil | Kg | |||

| Cr | Cor | mm | r/min | r/min | |||||||

| 4200 | 10 | 30 | 14 | 0.6 | 7.7 | 5.9 | 18 | 3.969 | 15000 | 20000 | 0.049 |

| 4201 | 12 | 32 | 14 | 0.6 | 7.75 | 6.15 | 18 | 4.763 | 14000 | 18000 | 0.053 |

| 4202 | 15 | 35 | 14 | 0.6 | 9.75 | 9 | 20 | 4.763 | 12000 | 16000 | 0.059 |

| 4203 | 17 | 40 | 16 | 0.6 | 11.7 | 10.4 | 18 | 5.556 | 11000 | 14000 | 0.09 |

| 4204 | 20 | 47 | 16 | 1 | 16.4 | 16 | 18 | 7.144 | 8800 | 12000 | 0.14 |

| 4205 | 25 | 52 | 18 | 1 | 16.3 | 16.9 | 20 | 7.144 | 7700 | 10000 | 0.16 |

| 4206 | 30 | 62 | 20 | 1 | 26 | 20.8 | 18 | 8.731 | 6400 | 8600 | 0.26 |

| 4207 | 35 | 72 | 23 | 1.1 | 35.1 | 28.5 | 18 | 10.31 | 5500 | 7300 | 0.4 |

| 4208 | 40 | 80 | 23 | 1.1 | 37.1 | 32.5 | 20 | 11.113 | 5000 | 6700 | 0.5 |

| 4228 | 45 | 85 | 23 | 1.1 | 39 | 36 | 20 | 11.509 | 4600 | 6100 | 0.54 |

| 4210 | 50 | 90 | 23 | 1.1 | 41 | 40 | 22 | 11.509 | 4200 | 5150 | 0.58 |

| 4301 | 12 | 37 | 17 | 1 | 13 | 7.8 | 0.092 | ||||

| 4302 | 15 | 42 | 17 | 1 | 14.8 | 9.5 | 18 | 5.556 | 11000 | 14000 | 0.12 |

| 4303 | 17 | 47 | 19 | 1 | 19.5 | 13.2 | 9400 | 13000 | 0.16 | ||

| 4304 | 20 | 52 | 21 | 1.1 | 23.4 | 16 | 18 | 7.144 | 8300 | 11000 | 0.21 |

| 4305 | 25 | 62 | 24 | 1.1 | 31.9 | 22.4 | 18 | 9.525 | 6900 | 9200 | 0.34 |

| 4306 | 30 | 72 | 27 | 1.1 | 41 | 30 | 16 | 11.906 | 5800 | 7700 | 0.5 |

| 4307 | 35 | 80 | 31 | 1.5 | 50.7 | 38 | 16 | 13.494 | 5100 | 6800 | 0.69 |

| 4308 | 40 | 90 | 33 | 1.5 | 55.9 | 45 | 16 | 15.081 | 4600 | 6100 | 0.95 |

| 4309 | 45 | 100 | 36 | 1.5 | 57.6 | 46 | 16 | 16.669 | 4100 | 5500 | 1.25 |

| 4310 | 50 | 110 | 40 | 1.5 | 70.4 | 77.7 | 16 | 18.256 | 3700 | 5000 | 1.7 |